YOUR PARTNER

FOR DRIVE ELEMENTS

AND EVERYTHING THAT COMES WITH IT

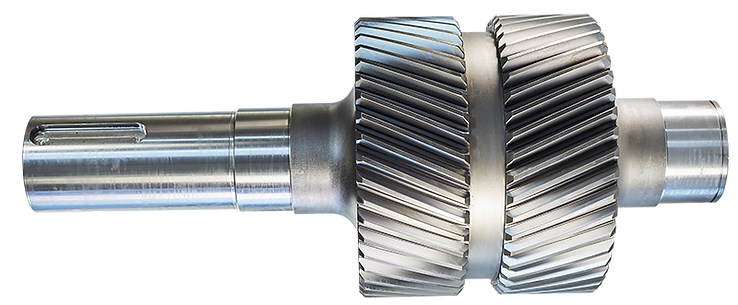

GEARS

INSIDE & OUTSIDE

Gears inside & outside –

precisely manufactured, precisely matched

Whether pinion shafts, gears, splined shafts or splined hubs –

We produce high-precision gear components for a wide range of applications. Thanks to our decades of experience and membership in the SEW Group – a leading global provider

in drive technology – we combine global engineering know-how with the flexibility and hands-on mentality of a well-coordinated team on site in Neuried.

Modules, profile shifts, crowning, helix angles, tip relief, and pressure angles are not foreign concepts to us; they are part of our daily practice. Using state-of-the-art CNC gear cutting machines, we implement your requirements efficiently, with repeatable accuracy, and with the highest quality.

Our manufacturing capabilities at a glance:

→ Spur gears

Ø 10 mm to 1600 mm, module 0.3 to 20 and larger on request

→ Sprockets

Ø 10 mm to 1600 mm, pitch 5 mm to 100 mm from 1/4 inch to

3 inch pitch

→ Racks

Up to module 20, also available in ground finish on request

→ Milling and slotting

Of splined shaft profiles according to DIN 5461 to DIN 5465,

DIN 5471 and DIN 5472, involute connections according to

DIN 5480, serrated profiles according to DIN 5481

→ Toothed hubs and splined shaft profiles

DIN 5482

→ Internal gearing

Up to module 12, Ø 1000 mm outside and inside, 1300 mm circulation Ø

Technology is our driving force – innovation is our standard. In our state-of-the-art production center, equipped with the latest machinery, we implement the most sophisticated gearing and drive solutions. With digitally networked technology, maximum precision, and automated processes, we produce highly customized components in Kehl – from individual parts to complex series. All this in an environment that combines efficiency, quality, and the future.

INSIDE & OUTSIDE

GEARS

Gears are generally divided into internal and external gears. With internal gears, the teeth/wedges in the bore face inward. With external gears, they face outward.

Internal gears are predominantly manufactured on gear shaping machines. The shaping blade performs a reciprocating and rotating motion while the workpiece rotates around its own axis. Gear shaping is also used in the production of internal gears in blind holes, as well as for external gears with no run-out.

The manufacturing process for external gears is called gear hobbing. It is characterized by its high flexibility and is the most economical and productive method for manufacturing external gears. A wide variety of workpieces can be produced with any number of teeth, helix angles, profile shifts, and profiles. Axial milling is typically used. Here, the hob is shifted axially toward the workpiece center. The workpiece and hob are intersected according to the helix angle and lead angle.

CONTACT

CABA-BLIND

OUR ADDRESS

CABA-BLIND

Georg-Grether-Str. 6

77743 Neuried

Located in the BASIC Industrial Park

Phone: +49(0)78 54-96 68-0

Fax: +49(0)78 54-96 68-66

Contact form:

ATTENTION! By submitting this form, you accept our privacy policy, which you can access here. This policy provides you with all the information about which of your data is collected and processed.